AIRBEST Vacuum Suction Cup for Glass Handling: Suitable for Different Plane Glass

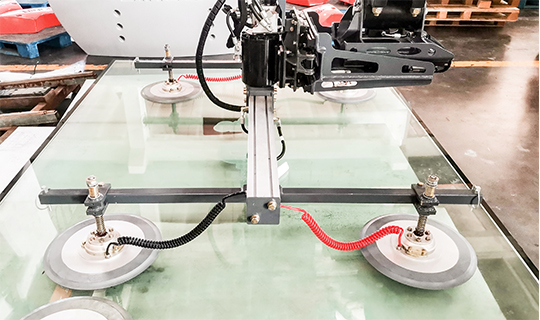

The vacuum technology we mentioned here is negative pressure, to do the action of picking up, placing, handling, transfer, destacking of glass, etc.

The diameter of vacuum suction cup SFG series from 125-400 mm, with a large effective suction area.

EPDM material could be used in a high UV environment.

Mark-free material could meet the requirement of no visible mark left on the glass after handling.

SNT series special gripper has integrated vacuum generation, and handling of the sensitive or porous workpiece, such as solar cell.

The vacuum technology we mentioned here is negative pressure, to do the action of picking up, placing, handling, transfer, destacking of glass, etc.

The comment requirement of handling glass panel by vacuum suction cup is no mark after handling. It requires mark free material for vacuum suction cup.

Different series products to meet different applications in glass handling.

Customized design is available.

Fast delivery with stable quality.

We have some certificates, such as CE, ROHS, etc.

It depends on the type of workpiece, air-tight or porous, and how many pieces of vacuum suction cup to connect with, etc. Please contact us for details.

It's better to describe us the special environment, such as high humidity, high temperature, corrosive, explosive, static, etc. Then we could check for you.

The selection is determined by the factors, including whether the type of workpiece is air-tight or porous; requires a short work cycle or not; the pressure of compressed air, etc.

Glass is a traditional industry and one of the bulk building materials. Glass is widely used in many industries such as automotive, electronics, construction, photovoltaic, pharmaceutical, etc.

There are different places where glass is used widely, like a hotel, airports, shopping malls, houses, offices, etc. Presently, there are several places where glass decoration is a must like at airport, hotel, lift, restaurants and other places. Glass is not only used for door and windows but there are several other places where glasses are used widely. Glass product installation is challenging work and very smoothly it needs to be done. If you are a professional and you will use glass for installation, then you must know how it is installed and what the complete process is. The glass industry is very trendy and the growth of the glass industry is increasing day by day.

The vacuum technology we mentioned here is negative pressure, to do the action of picking up, placing, handling, transferring, destacking of glass, etc.

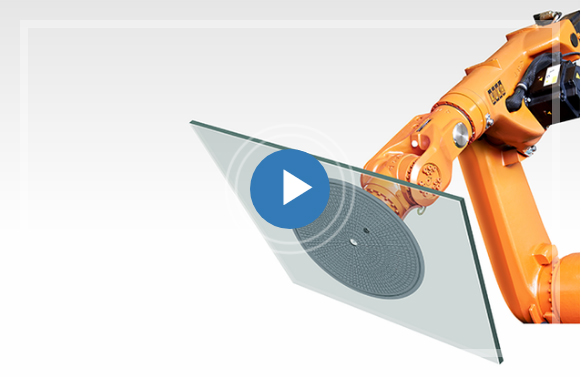

Glass is a versatile material and its chemical and physical properties permit it to use in several sectors with different applications. Mainly, glass is widely used in the automotive and architecture sectors! The main thing to remember is, that the glass workpiece is very sensitive, and in most cases, vacuum technology handles the glass because it protects the glass and protects the glass from damage as well. Vacuum technology is mainly used in the glass industry because it holds the glass which helps to protect glass from breaking! You can use vacuum technology for the glass industry very easily. There are different types of vacuum technology available and you may choose any type as per your need and requirement. A vacuum suction cup for glass handing provides a better solution for the glass industry.

In the glass industry, we use vacuum suction cup SFG series, which has a vulcanized sealing ring and steep sealing lip, with a big diameter, it's generally used for handling big glass. For the small piece of glass, if you want no visible marks on the surface glass after handling, we have vacuum suction cups made of mark-free material; you can choose the SNT series, SBA series, SPF series, SPJ series, etc.

If you are looking for a professional manufacturer who offers different types of vacuum suction cups for glass handling, you should choose us! We are one of the professional vacuum suction cup manufacturers and we offer vacuum suction cups for the glass industry as well. You can provide us with different shapes and sizes and based on that we can produce suction cups. We are also able to provide you with customized suction cups as well. Some types of suction cups are most commonly used in the glass industry and you should check that one! You can check our SGF series suction cups and you may choose any type of suction cup vacuum suction cup for glass handing as per your need and requirement.

The glass panel is widely used in electronics such as mobile phones and computers, household appliances such as refrigerators, induction cookers, etc. The requirement of handling glass panel is no visible mark on the glass, AIR BEST has SNT series special vacuum suction cup for glass handing, integrated vacuum generation on Bernoulli principle, special material on the bottom could meet different requirement, NBR, food-grade material and mark-free material for option.

Using vacuum technology, it's quite easy to transfer glass panels from one side to another side. Vacuum technology reduces accidents in the glass industry and will also help to increase production volume as well. To manufacture glassware, large types of compressed air and vacuum are required always. The main important thing is high quality and reliability. During production, if any accident occurs or creates glass damage then it tends to be a huge loss. So, the manufacturer always uses vacuum technology to make proper glassware very safely. There are different types of options available like mark-free material and food-grade material as well.

In the glass industry, vacuum suction cups for glass handling especially for handling smooth, flat, thin, or hot glass, should choose different materials to meet the special conditions of the glass. Mark-free material is used for no visible mark request, temperature resistance material is used for handling high-temperature glass, EPDM material could be used in areas with high UV or ozone levels, etc.

It's very essential to choose the proper parts for different glass products. There are different types of glass industries available in the market. Based on their production type they need vacuum technology. They need different shapes and sized vacuum suction cups. You just need to check and select the professional suction cups as per your need and requirement. Vacuum technology is one of the professional technologies which help in the automation industry and glass industry. There are different types of sectors where you may use such vacuum technology. Vacuum suction, vacuum grippers, and many other types of vacuum applications are available.

During handling glass, vacuum suction cups for glass handing touch the surface of glass directly. For normal vacuum suction cups, there is a visible mark left on the glass after handling, especially the high-temperature glass. In this case, we need to choose the vacuum suction cup with mark-free material and high-temperature resistance, there will be no visible mark after handling.

You just need to select the professional technology as per your need and requirement. Vacuum technology is mainly used to create any type of job smoothly. This will help to move small to large applications from one place to another. This helps to progress the production and makes your production easy. Choose a professional deal from us and a smooth production process. Vacuum technology helps to glass industry to run its business without any problem. Using vacuum technology they can easily start production and able to earn more products. This entire process is simple and easy. We, AIR BEST is always ready to provide you the professional service at a professional price.

Sealing is very important for handling glass, vacuum suction cup SFG series is designed for handling glass. There are two types of sealing lip options. One is a flat sealing lip, little movement during handling prevents damage to the surface of the glass. Another is steep sealing lip, optimum damping effect when gripping glass.

If you are having the glass industry and want to run your production smoothly, then you should choose the SFG series for that! We particularly designed this series for the glass industry. If you are looking for a quality product, then you should place an order with us! We can able to produce different types of vacuum suction cups or grippers as per your need! You have to mention the size and length of the product, dimension, and other details as well. This is another important sector where vacuum applications play an important role. This is the sector where you have to use each component or product very carefully. Glass industry is something which you need very careful decisions. So, for this industry, you may use vacuum suction or vacuum caps.

Vacuum suction cups for glass handing touch the surface of glass directly, it's important to choose the suitable type of vacuum suction cups, that will not damage the glass.

It's always better to choose the perfect suction cups for your glass products. There are different types of glass products manufacturing is going on! Now, based on your production house, you may choose anyone. There are several areas where you can apply such vacuum suctions. You can easily carry uneven surface products like body panels, cardboards, and tubes. You will be able to move goods from one place to another. Such vacuum suction is good for handling fragile workpieces, electronic components, etc. You have to handle any type of flexible workpieces, like shrink-wrapped or flexible workpieces, etc.

Vacuum technology in glass industry applications is safe. On the premise of choosing a suitable vacuum suction cup and level compensator, the handling is safe and reliable.

It's always better to use vacuum technology for the glass industry! Glass is a very smooth product and it has a high chance of breaking the entire surface very easily. During production, it's always better to take care of it properly. In vacuum technology there are different types of suction cups and grippers available and using the proper size, you can able to grab the glass and shift it from one place to another. This will reduce accidents and this will also increase the production line. Vacuum technology is always professional because it offers several benefits. It reduces damage and it will also help a production to run their glass production easily.

The vacuum suction cup for glass handing is the link between the glass and the handling system, it is used to grip or move the glass. The ambient air pressure presses the vacuum suction cup against the workpiece as soon as the ambient pressure is greater than the pressure between the vacuum suction cup and glass. The vacuum generator provides the vacuum level that is requested for handling tasks.

There are different types of vacuum suction cups available in the market and you may choose anyone as per your need! You have to know the proper shape and size to complete. This is another type of vacuum suction cup. This cup has a round shape and is suitable for handling any type of flat workpiece. Using suction cups, you can grip the product very fast and move without any hesitation. As it has a flat shape and also has a small volume. The flat suction cup is another professional type of suction cup which is an oval type. This type of vacuum suction cup is specially designed for narrow and long workpieces. As it has a small volume and flat shape, so, it will work fast and very precisely.

The vacuum suction cup for glass handing is suitable for handling flat glass (float glass) or coated glass.

To know more details about vacuum technology in the glass industry, you can consult with us! We have almost 15 years of experience in this field. If you are looking for superior quality and professional shape and size vacuum suction caps for your plant or industry, just choose AIR BEST. We are one of the professional vacuum suction manufacturers who offer bulk quantities within time. If you place a bulk order, we will also provide a great discount and attractive offers! We will deliver the product on time. you have to follow some basic steps and place the order. Once received the payment we will start manufacturing. We always focus on customers' needs and order details and deliver products on time.

A vacuum suction cup could be used for handling glass containers.

Yes, if you have a production process for glass containers then to run your production smoothly, you can use container glass always. The special use or working environment should be clarified when choosing the correct vacuum suction cup. Different material of vacuum suction cup has their features; some of them are used in a specific environment. You will get different types of suction cups with different shapes, sizes, and materials. You need to choose the proper suction cup for different applications. There are different types of industries available and you may choose the proper suction cup for your industries.

For handling glass containers with vacuum suction cups, the most important thing is there should be enough surface on the glass containers for the vacuum suction cups to touch completely, then it could be gripped by vacuum suction cups.

You have to provide us with your glass container measurements. We need proper shape and size details and based on that we will design a suction cup or vacuum gripper properly. Our process is simple and easy. We need proper measurement and shape and size details to manufacture appropriate vacuum suction cups for glass handling which help to grip the glass container during production. It helps to run production successfully and it will also provide several benefits. Vacuum suction cups are often used as a gripper. Mainly in the automation industry or glass industry, such types of vacuum suction cups are very essential. This helps to shift small parts using suction cups from one place to another.

In the glass industry, the handling of glass is normally done by vacuum suction cups. Before choosing a suitable vacuum suction cup, we need to check some information about glass such as weight, size, temperature, surface condition, clean or not, etc. And others such as handling work cycle, handling direction, etc.

If you will purchase a suction cup, it helps to move small parts and products from one place to another very easily. It helps to reduce the workload and it will also save you valuable time. This type of suction cup is professional for the glass industry, automobile industry, metal industry, etc. There are several industries like beverage, electronics, wood, metal, semiconductor, and automotive where people should buy suction cups. The suction cup grips the surface of the product and it does not attach to the suction cup itself. The suction cup activates vacuum generators and draws out the air and it creates a vacuum. This suction cup includes atmospheric pressure which holds the workpiece.

The life of vacuum suction cups for glass handing in testing is more than one million times gripping. The actual life depends on the working condition.

The more you will use suction cups, the more it will reduce their operational capability. If you will use it daily several times then after a certain time it does not work! But if you will choose a vacuum suction cup for the glass industry you require quality material. If you will get quality material, then it will last long. Another professional advantage is, that if you will choose our product, we can produce any size, shape, and colorful products at a professional price. We can customize suction cups at a professional price. We have an experienced team and designers and we are ready to provide the professional opportunity. We have a simple processing system and you have to follow that system to get the professional suction cups.

AIR BEST provides technical support on model selection, application solutions, installation guidance, etc. To make sure the vacuum suction cup is suitable for the required application, the AIR BEST engineer will give you professional suggestions with a quick response.

We are ready to provide a professional suction cup for glass handling which lasts long. We also provide you with a guide on how to use and maintain a suction cup properly. People who don't know how to use suction cups for the glass industry and don't know how to maintain, they face lots of problems because if you don't know how to operate then suction cups do not stay long. Try the professional quality suction cup and use it for your glass industry.

Whether you are an eCommerce seller or a whole seller or distributor, we are always ready to give you professional quality vacuum suction cups for glass industries along with professional advantages. You will be able to get an attractive discount as well. It helps to save some money. Grab the professional deal online now! We can able to provide you the bulk quantity of vacuum suction cups. You can choose any design, shape, and size as well. Improve your production process and increase the production line by using suction cups. Choose the professional suction cups and improve the production line as well. Glass industry will increase its production volume much if they will use the suction cup for their productions. Choose the professional suction cups now from us and place an order!