Basic Vacuum Generator

- AGE Series

- ABT Series

- ABP Series

- ABQ Series

- AEVC Series

- ALS Series

- AZR Series

- ABM/ABX Series

- ACV Series

- AZH Series

Various types of vacuum generators for different industries.

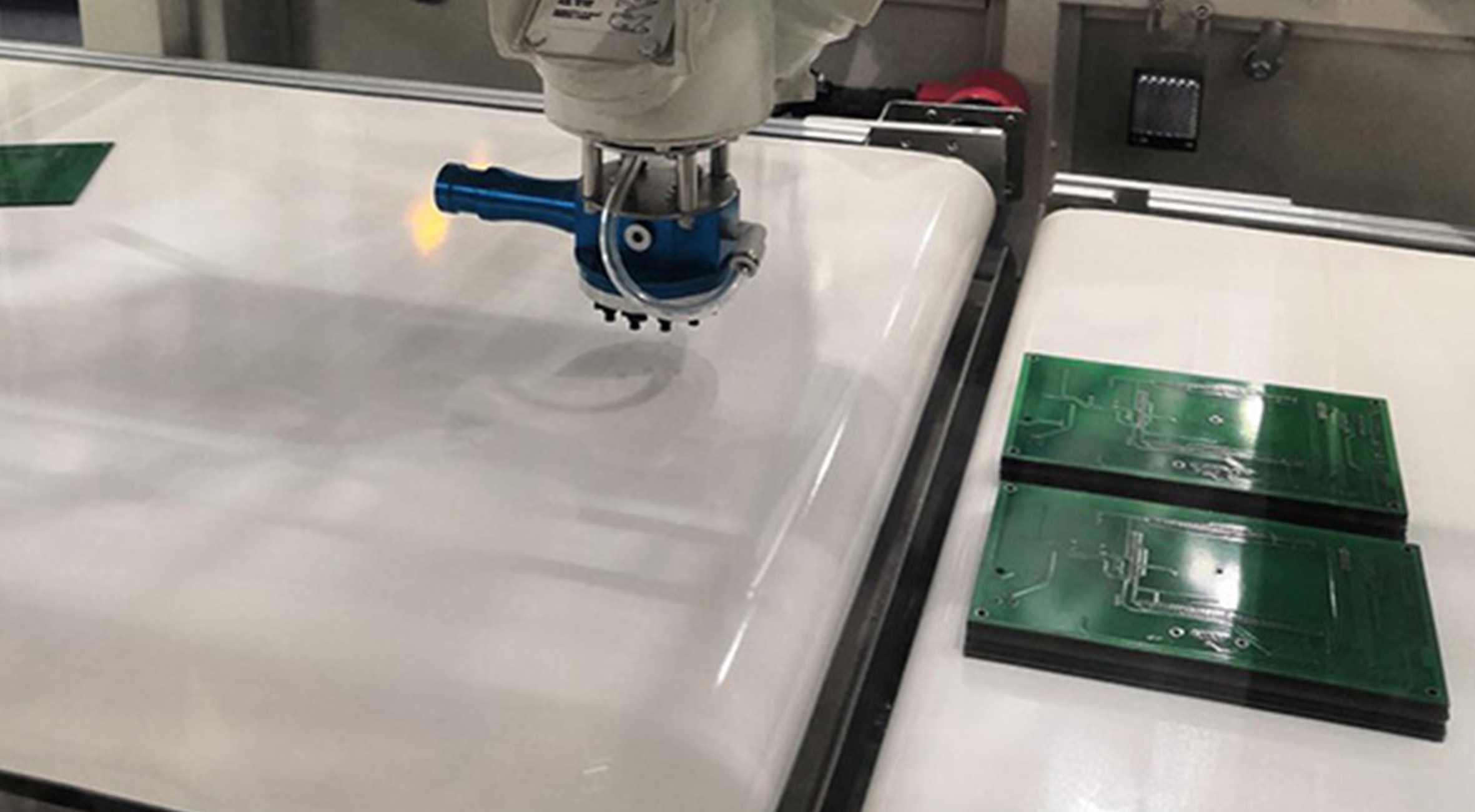

Integrated vacuum generator of small size is popular in the electronics industry.

High efficient and energy-saving vacuum generator

High vacuum level type and large vacuum flow type for option.

AIRBEST have various of vacuum generators used in different industries. There are basic vacuum generator, multistage vacuum generator, integrated vacuum generator, conveying vacuum generator, large flow vacuum generator, mini vacuum generator, linear vacuum generator, high pressure vacuum blower and so on.

AIRBEST vacuum generators are widely used in many industries. We will suggest suitable vacuum generator based on real application to meet different vacuum flow and vacuum level requirement.

For example, a pneumatic vacuum ejector, also known as a pneumatic vacuum generator or pneumatic ejector, is a device that uses compressed air or gas to create a vacuum. It is commonly used in various industries for applications such as lifting, handling, and conveying objects or materials.

AIRBEST vacuum generators are widely used in many applications. The main industries are electronics, packaging, automotive, plastic, metal sheet, glass and wood.

Vacuum generator is a new, efficient, clean, economical and small vacuum component that uses a positive pressure air source to produce negative pressure.

The working principle of the vacuum generator is to use the nozzle to spray compressed air at high speed, form a jet at the nozzle outlet, and produce coiling flow.

Under the action of suction, the air around the nozzle outlet is constantly sucked away, so that the pressure in the adsorption chamber falls below atmospheric pressure to form a certain vacuum degree.

We would like to have distributors in different countries, please contact us if you need.

We have some certificate, such as CE, ROHS, etc.

It depends on the type of workpiece, air-tight or porous, and how many pieces of vacuum suction cup to connect with, etc. Please contact us for details.

It's better to describe to us the special environment, such as high humidity, high temperature, corrosive, explosive, static, etc. Then we could check for you.

The selection is determined by the factors, including whether the type of workpiece is air-tight or porous; requires a short work cycle or not; the pressure of compressed air, etc.

A pneumatic vacuum generator is a kind of vacuum component device.

The working principle of a pneumatic vacuum generator: It uses a positive pressure air source to produce negative pressure, which is lower than atmospheric pressure. This negative pressure can be used as suction.

It can also be used as the rapid flow of compressed air to form a certain degree of vacuum.

A pneumatic vacuum generator forms an instantaneous vacuum, which is usually combined with a vacuum suction cup or vacuum suction device to carry out material adsorption, transportation, and fixation on various occasions.

AIRBEST has a strict quality control system and has obtained the ISO9001 certificate, certified by TUV SUD group.

For the quality management of pneumatic vacuum generator, first of all, we should do a good job of quality management from the R&D stage, test the product performance before the official sale, and then test the product in batch production. Only when it meets the acceptance standard can it be sold.

Secondly, there are operation instructions for each production link, training relevant operators and quality inspection personnel to master the operation contents and inspection standards of each link; audit supplier qualification, select high-quality raw materials and parts suppliers, and sign relevant quality requirements, technical requirements and acceptance standards and other documents.

Then, after the pneumatic vacuum generator is manufactured, the quality inspector should carry out the inspection, the inspection ratio is 100%, to ensure that each pneumatic vacuum generator is qualified, before entering the warehouse for delivery.

According to the structure, pneumatic vacuum generator can be divided into single-stage vacuum generator (simple structure, small volume, suitable for vacuum suction and transportation of each station in rapid motion system), multi-stage vacuum generator (large vacuum flow, which can be used for grasping and transporting porous workpiece) and combined vacuum generator.

According to the function, it can be divided into basic vacuum generator and integrated vacuum generator Vacuum generator (integrated with control, filtration and noise reduction, which can realize integrated vacuum absorption, generate or destroy vacuum, and energy saving effect) and conveying type vacuum generator (easy to install, adjustable vacuum value and vacuum flow, applied to suction and discharge of small particles or Powder Flake solids).

The cost performance of the AIR BEST pneumatic vacuum generator is very high. The price of the AIR BEST pneumatic vacuum generator is very competitive. In terms of quality, it can be comparable with internationally famous brands.

Our customers and dealers can use and sell them with confidence. The price of the AIR BEST pneumatic vacuum generator is very competitive, and our dealers and customers can accept it very happily.

Pneumatic vacuum generators are widely used in various fields of industrial automation, mechanical equipment, and robots, such as electronics, packaging, woodworking, glass, food, photovoltaic, printing, injection molding, sheet metal, automobile manufacturing, semiconductor, and other industries. The application scenarios include: picking, handling, palletizing, shifting, fixing, grabbing, etc.

The pneumatic vacuum generator uses positive pressure compressed air.

When the compressed air enters the air supply port, it will produce an acceleration effect when passing through the narrow nozzle inside the pneumatic vacuum generator, so that it can pass through the diffused cavity at a faster speed. At the same time, the air inside the diffusion chamber will be rapidly ejected together.

Because the air in the diffusion chamber and the compressed air flow out very quickly together, the instantaneous vacuum effect is produced in the diffusion chamber. When the vacuum pipeline is connected with the vacuum port, the vacuum generator can extract vacuum from the vacuum pipeline to form suction.

a) The pneumatic vacuum generator uses air to generate vacuum, the air is free, and the cost of using vacuum generators is very low.

b) The pneumatic vacuum generator is small in size and flexible in installation, and can be used in different equipment and working positions.

c) The pneumatic vacuum generator produces vacuum quickly and has high efficiency.

d) During the operation of pneumatic vacuum generator, no harmful substances will be produced, which is clean and environmentally friendly.

A pneumatic vacuum generator is a new, economical, efficient, and clean vacuum component. As long as there is compressed air, it is very convenient to obtain negative pressure. It has been widely used in industrial automation.

The application scenarios include: picking up, handling, palletizing, shifting, fixing, grabbing, etc. It covers a wide range of industries, such as woodworking, glass, packaging, food, photovoltaic, electronics, sheet metal, automobile manufacturing, semiconductor, printing, injection molding, etc.

The pneumatic vacuum generator is installed between the air supply source and the end grabbing parts (such as vacuum sucker, vacuum suction device, etc.).

After the negative pressure is generated by compressed air, the relative vacuum degree is generated between the end matching grasping part so that the workpiece is firmly absorbed.

If there are fine substances such as dust in the air, a filter can be installed. If a vacuum breaking function is needed, a corresponding valve can be installed.

The function of a pneumatic vacuum generator is to generate a vacuum.

By adding other devices, the function of vacuum breaking can be integrated to realize automatic control. If the requirements of vacuum degree and vacuum flow rate and application scenarios are specified, the suitable specifications and models can be quickly selected. If the requirements of vacuum degree and vacuum flow rate cannot be specified, it is necessary to further understand:

a) The characteristics of the work-piece to be grasped, such as smooth or rough surface, clean surface or oil stain, whether the work-piece is easy to deform, the shape, size, and weight of the work-piece, whether the air permeability of the work-piece is very strong, whether it is porous, etc.

b) Operation speed, whether there is a speed requirement for grasping or handling

c) Vacuum breaking function, is it necessary.

d) How many vacuum cups can be driven by a vacuum generator.

Through model selection, we can tell our sales staff about the model.

If we can't determine the specific model, we can tell the product requirements or application scenarios to the sales staff of AIRBEST. We have a detailed product selection manual, which allows customers to select the right vacuum generator very quickly.

You can also contact AIR BEST by phone call 0086-572-6388266 (8:00-17:00 on weekdays) or email: info@airbest.com

Pneumatic vacuum generator uses compressed air to generate negative pressure, a relative vacuum degree is generated between the end matching grabbing part and the work-piece, so that the object is firmly absorbed; there are also conveying type vacuum generators for conveying granular objects or small fragments.

The application scenarios include: picking, handling, palletizing, shifting, fixing, grabbing, etc.

Compared with other brands of pneumatic vacuum generators, AIR BEST has complete varieties and specifications of pneumatic vacuum generators, which can meet the needs of different application scenarios. Customers can directly purchase vacuum generators from AIR BEST. Or we can provide design pneumatic vacuum generators services. Airbest's pneumatic vacuum generator has a high-cost performance ratio.

In terms of quality, it can be comparable with internationally famous brands. Our customers and dealers can use and sell them with confidence. The price of AIR BEST pneumatic vacuum generator is very competitive, and our dealers and customers can accept it very happily.

After-sales service of pneumatic vacuum generators includes installation guidance, use guidance, and problem-solving. After receiving the pneumatic vacuum generator from AIR BEST, if you have any questions about the installation or use of the product, you can contact our sales staff, and we will provide installation and use instructions.

If there is any problem during the use of a pneumatic vacuum generator, please also contact AIR BEST. Our team including sales staff, technical engineers, and quality engineers will solve the problem. If you have any questions, please contact: 0086-572-6388266 (weekday 8:00 ~ 17:00), email: info@airbest.com

At present, AIR BEST has agents in a few countries. If you want to be an agent of AIR BEST, you can contact our sales personnel for in-depth negotiation.

Contact information: Tel: 0086-572-6388266 (working day 8:00 ~ 17:00), email: info@airbest.com