Energy-efficient nozzle design

With energy-saving control device

With normally open vacuum supply valve

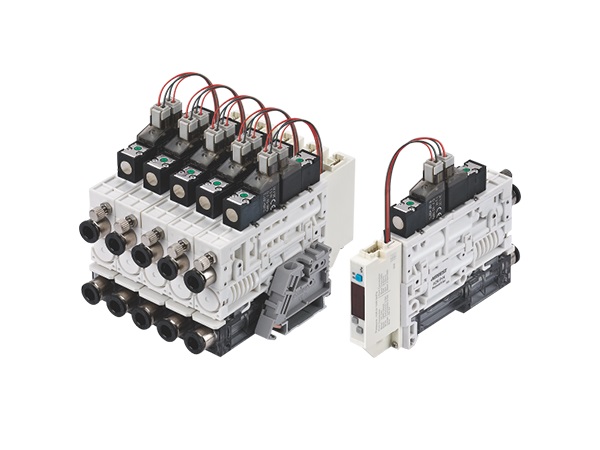

Small size and light weight. The volume is 85cm³

Transparent filter housing

Single body with L bracket, DIN guide rail installation for integrated body, centralized air supply

Vacuum flow increased by 50% and air consumption decreased by 30%

Air consumption reduced by 90% (compared with non-energy saving type)

Power outage or power off does not affect vacuum producing and prevent the workpiece from falling

The device is compact and can be installed directly in the handling system

The cleanliness is visible and easy to replace

Simple installation, can be installed directly on the distribution box

Integrated vacuum generator for handling airtight and slightly porous workpieces

Vacuum producing and monitoring in automation systems

For robot handling applications and linear axes

Pick and place applications with very short time

Used for systems that require high dynamic handling of workpieces and with limited space

Usually used for handling small parts in fully automated systems