Features

Features  Features

Features

Large area support structure at the bottom

Flat and short compressed stroke

Split structure design

Available in various sizes

Selection Guide

Selection Guide SH 40 N

① ② ③

| ① Series | ② Diameter | ③ & Material Hardness |

| SH | 40 - φ40mm 80 - φ80mm | N - NBR 55 |

| 50 - φ50mm 100 - φ100mm | WS - White silicone 50 | |

| 63 - φ63mm 125 - φ125mm |

Technical parameters

| Model | Pull-out force N | Inner volume cm³ | Weight g | Recommended hose dia. mm | MPQ pcs |

| SH40 | 56 | 4 | 13.5 | 8 | 1 |

| SH50 | 88 | 6.9 | 25.1 | 8 | 1 |

| SH63 | 140 | 11.5 | 47.9 | 8 | 1 |

| SH80 | 226 | 24 | 75.4 | 8 | 1 |

| SH100 | 353 | 55 | 149.7 | 10 | 1 |

| SH125 | 552 | 85 | 263.6 | 10 | 1 |

Note: Testing vacuum level -60kPa, a workpiece with a smooth and clean surface. The data of pull-out force as above are figured out without considering safety factors.

The data may be different according to different workpiece surfaces. Recommend the length of the vacuum hose to be as short as possible, max 2m.

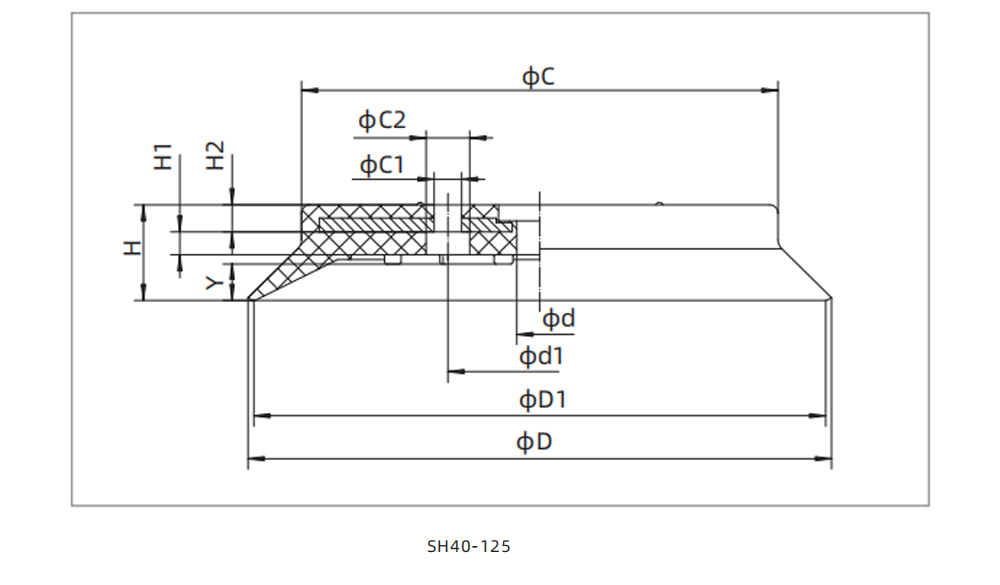

Dimensions

Dimensions

| Model/Size | D | D1 | d | d1 | H | H1 | H2 | C | C1 | C2 | Y |

| SH40□ | 42 | 40 | 6 | 18 | 11.5 | 3.5 | 3.5 | 32 | 3-φ4 | 3-φ6.5 | 3.5 |

| SH50□ | 52 | 50 | 6 | 18 | 11.5 | 3.5 | 3.5 | 42 | 3-φ4 | 3-φ6.5 | 3.5 |

| SH63□ | 65 | 63 | 8 | 34 | 14.5 | 4.5 | 4.5 | 51 | 4-φ5 | 4-φ8 | 3.5 |

| SH80□ | 82 | 80 | 8 | 34 | 16.5 | 4.5 | 4.5 | 68 | 4-φ5 | 4-φ8 | 4.5 |

| SH100□ | 103 | 100 | 10 | 40 | 21 | 5 | 6 | 80 | 4-φ6 | 4-φ9.5 | 7.5 |

| SH125□ | 127 | 125 | 10 | 40 | 21 | 5 | 6 | 104 | 4-φ6 | 4-φ9.5 | 7.5 |

Note: The dimensional tolerance conforms to GBT3672.1-2002-1 M3 rubber product dimensional tolerance standard

Mounting Accessories

Mounting Accessories | Model | Vacuum port direction | ||

| Nil | R1 | LR1 | |

| SH40□ | SH40□-M10F SH40□-G2F | SH40□-R1-M14M | SH40□-LR1-M10F |

| SH50□ | SH50□-M10F SH50□-G2F | SH50□-R1-M14M | SH50□-LR1-M10F |

| SH63□ | SH63□-M10F SH63□-G2F | SH63□-R1-M16M | SH63□-LR1-M10F |

| SH80□ | SH80□-M10F SH80□-G2F | SH80□-R1-M16M | SH80□-LR1-M10F |

| SH100□ | SH100□-M12F SH100□-G3F | SH100□-R1-M16M | SH100□-LR1-M10F |

| SH125□ | SH125□-M12F SH125□-G3F | SH125□-R1-M16M | SH125□-LR1-M10F |